- On Sale

- Build Your Own

- Used Equipment

- New Equipment

- Trade In

- Parts

- Service

- Aged Equipment Clearance

- Buy Online

- Precision Farming

-

- The Basics Of Haymaking

- Round Baler Basics for a 460M Round Baler

- How to Load Net Wrap on a 460M Round Baler

- Top 10 Implements For Livestock Operations

- How to store large round bales

- How to set up and operate a mower conditioner

- How to use a mechanical grapple

- Pick up grass clippings using a drive-over mower deck

- Careers

John Deere N536 No-Till Air Drill

N536

No-Till Air Drill

- Adjust down pressure with TruSet™ In-Cab downforce

- See the flow of seed & fertilizer from the cab with RelativeFlow™ blockage monitoring

- Quick Change Blade enhancement of the ProSeries™ Opener reduces change time by up to 45%1

- Convenient dual-row spacing hydraulics

- Get a Quote Build Your Own PowerGard Extended Warranty Evaluate My Trade

- Find My Location

- Payment Calculator

- View Product Brochure

-

Share

Get A Quote

Fields with asterisks* are required. Please email our helpful staff with any questions or comments using the contact form.

Loan Calculator

Use the Loan Calculator to help you determine the financing and payment options that are best for you.

**The accuracy of this calculator and its applicability to your circumstances is not guaranteed. You should obtain personal advice from qualified professionals. This information is provided for illustrative purposes only and does not constitute an application. This notice does not guarantee loan approval, nor is it an offer or commitment to make a loan to you on the above terms.

Features

The Total Seeding Solution – experience the John Deere advantage

John Deere has the seeding solutions that go above expectations with a complete line of everything needed in small grains. Offering a variety of openers for your chosen practice in a variety of configurations and sizes. All with integrated technology throughout the seeding train allows for effortless setup and seamless documentation.

Total seeding solution

Total seeding solution

Setting up a John Deere seeding train is quick and easy with the plug and play technology. All data and technology operate through the Gen 4 display and ultimately up to John Deere Operation Center™ that can be viewed from anywhere at any time. Not only does the complete John Deere seeding solution all operate through one display but it eliminates the difficulty and time-consuming tasks of setting up extra displays and harnesses.

John Deere tractor paired with John Deere tool and cart

John Deere tractor paired with John Deere tool and cart

With a complete John Deere seeding solution, there are multiple different onboard and offboard technologies shown below that improve the overall seeding production step. Many of these technologies are exclusive to John Deere. Each of these technologies bring different customer value that overall lead to the ultimate John Deere seeding solution!

Improve confidence and while reducing maintenance with the new AccuRate™ metering system

- Combination of stainless steel and composite materials ensure an entire corrosion resistant system

- Individual electric meters allowing for more precise seeding

- Up to 8x more accurate prescriptions with high fidelity prescription

- Start and stop each meter with SectionCommand™ Pro

- Accurately meter the correct amount of product on a curve with curve compensation

AccuRate™ meters showing eight individual sections

AccuRate™ meters showing eight individual sections

Calibrate faster and easier than ever before with EZCal™

- Easily calibrate from the side of the cart with the click of a few buttons 45% faster than the leading competitor

- Automatically weigh product and update MDV values eliminating potential user error

G5e Cart Side Display

G5e Cart Side Display

EZCal™ system

EZCal™ system

ActiveCal™ display Calibrate more frequently from the seat of the cab with ActiveCal™

- Calibrate the meters from the cab utilizing the tank scales

- Improved confidence that the correct seeding rates are being met

ActiveCal™ display

ActiveCal™ display

Save input cost with SectionCommand™Pro

- Control seed and fertilizer output by starting and stopping each individual meter section

- Eliminate skips and overlaps leading to reduced inputs and higher yields

Example of seeded field with SectionCommand™ Pro

Example of seeded field with SectionCommand™ Pro

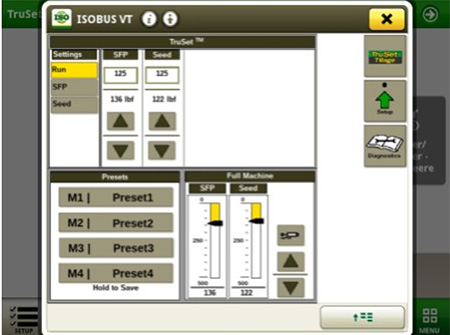

On the go, quick adjust downforce with TruSet™ from the cab

- Adjust downforce pressure to improve uniform emergence

- Set presets to quickly adjust from field to field

TruSet downforce display

TruSet downforce display

Monitor blockage row by row from the cab with RelativeFlow™

- Seed with confidence while monitoring each row

- Detect blockage early and know exactly where it is

RelativeFlow blockage sensors

RelativeFlow blockage sensors

AutoTrac™ Implement Guidance and AutoTrac Turn Automation

- Make every operator an experienced operator

- Precisely placed implements for more accurate seeding, less operator fatigue, and more productivity

- Hands-free turns within field headlands (with AutoTrac Turn Automation enabled)

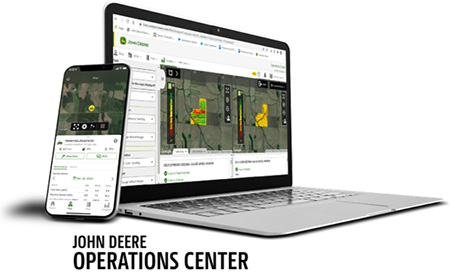

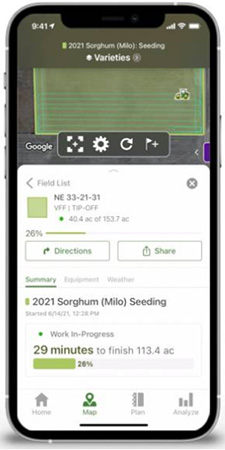

Operation Center Mobile

- View your data on the go; remotely monitor job quality, productivity, machine performance, and quickly make informed decisions

- Manage and monitor from anywhere at any time with near real-time field and machine updates

AutoTrac Turn Automation display

AutoTrac Turn Automation display

John Deere Operation Center™

- Setup and manage your farm operations: equipment, team, fields, and crop inputs

- Plan work in advance to increase job quality and efficiency with Work Planner

- Map based prescriptions can be used with variable rates

- Analyze this season’s results to improve next season’s crops

John Deere Operation Center web and mobile

John Deere Operation Center web and mobile

Operation Center Mobile

Operation Center Mobile

Connected Support

- Expert Alerts proactively notifies your dealer of any issues

- Remote display access allows for easy on the go support

Connected Support

Connected Support

For more information regarding Large Tractors and Precision Ag, view the following landing pages

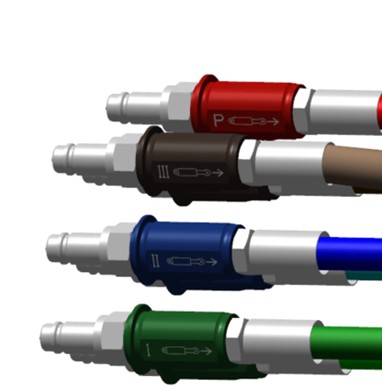

Color-coded hydraulic hose handles

John Deere color-coded hydraulic hose handles

John Deere color-coded hydraulic hose handles

Color-coded hoses plugging into tractor SCV

Color-coded hoses plugging into tractor SCV

These color-coded aluminum hydraulic hose handles make connecting hydraulic hoses from the air seeder and air cart to the correct Selective Control Valve (SCV) on the tractor easier than before. The anti-slip makes it easy to grip the hose and connect or disconnect from the back of the tractor. Each color is laser engraved with the John Deere logo and extend/retract icons to ensure proper matching to the proper function.

- Easily identify function of each hose

- Consistently match hose handles colors to rear couplers on tractor

- Easy to grip for connecting or disconnecting to the SCV

- Base equipment on all trailing air carts

- Base equipment on all seeding tools

No-till opener seeding with minimal maintenance from the ProSeries™ Opener

ProSeries Openers

ProSeries Openers

The ProSeries Opener is John Deere’s most advanced opener for your seed and separate fertilizer placement. When it comes to seeding precision, consistent seed depth, and uniform emergence in virtually all field conditions, you can superSEED your expectations with ProSeries.

Two of the three daily grease points were removed. The only remaining grease point is a yearly interval. The narrow seed boot travels behind the shadow of the blade, causing less soil disturbance. When attaching the boot to the shank, the bolt has been replaced with a flag pin. Now the flag pin is the wear point, not the casting, reducing overall maintenance. The seed press wheel is also redesigned; it has a narrow profile, a double row ball bearing, and is made of a flexible material. The quick-change blade feature reduces the time it takes to change each blade, saving time and money. Lastly, the seed tab is UV resistant and profiled similar to the trench. There is also the added option of the serrated closing wheel.

ProSeries Openers are in base equipment on all N500 and N500F Separate Fertilizer Placement (SFP), N500C, 1990 Central Commodity System (CCS™), and 1590 Air Drills.

The ProSeries Openers:

- Work not only in no-till conditions, but also in minimum or reduced-till conditions

- Provide 51 mm (2 in.) of free travel in the opener before spring down pressure takes over

- Benefit: allows the opener to move over uneven ground conditions and minimize the chance of the gauge wheels bulldozing soil in soft or mellow conditions

- The opener spring travels a maximum of 203-mm (8-in.) up or 150-mm (6-in.) down before the hydraulics react to uneven seedbeds

Confidence in rates from row to row with RelativeFlow™ Blockage sensing

With RelativeFlow Blockage sensing, operators can see the flow of both seed and fertilizer from inside the tractor cab. Sensors on all secondary hoses monitor the relative product flow row to row, giving you a better view of the flow rate of both seed and fertilizer from the cart to the opener from inside your tractor cab. This technology can help you identify any problems before a potential blockage occurs.

RelativeFlow Blockage is available in all run configurations on the following models (all widths):

- H500

- H500F

- P500

- P600

- N500

- N500F

- N500C

- 730LL

RelativeFlow Blockage is compatible with hydraulic drive carts: model year 2014 and newer 1910, all 19,381.5-L (550-bu) 1910 Carts, and C650 and C850 Air Carts.

Below are the Gen 4 display screens for the blockage monitoring system. For complete details and information, see the owner’s manual.

Blockage monitoring screen on Gen 4 display

Blockage monitoring screen on Gen 4 display

The RelativeFlow Blockage sensing chart shows the amount of flow through each sensor on the selected tower. Sensitivity for the blockage system can be adjusted if desired, as shown below.

Blockage Setup screen on Gen 4 display

Blockage Setup screen on Gen 4 display

Blockage warning sensitivity allows the producer to set and change the sensitivity of the sensors to meet their preferences and varying crop/fertilizer types. Increasing the sensitivity means the system is more likely to show a false blockage, while less sensitivity means the system is more likely to miss a blockage.

Multiple run-page alarm behavior options are available for selection.

Blockage sensitivities and alarm delays are all set up on one easy-to-navigate screen

Blockage sensitivities and alarm delays are all set up on one easy-to-navigate screen

Blockage alarm delays can be set up by clicking on the advanced settings button from the blockage set-up screen.

- A blockage delay is how long a blockage should occur before an alarm is sounded.

- The blockage alarm reminder is how often the alarm should sound when a blockage occurs.

- The meter on delay is the time from when the meter is turned on until the blockage sensor should start monitoring for blockage.

- The meter off delay is the time from when the meter is turned off until the blockage sensor should start monitoring to verify no flow.

For more detailed information, see the owner’s manual.

Air tools with RelativeFlow Blockage are not compatible with 1910 air carts with ground drive.

Operators can zoom into flow details by meter section when selecting blockage tiles

Operators can zoom into flow details by meter section when selecting blockage tiles

Operators can zoom into the row level to access row/sensor information and turn a sensor on/off independently

Operators can zoom into the row level to access row/sensor information and turn a sensor on/off independently

Blockage monitoring screen on Gen 4 display

Blockage monitoring screen on Gen 4 display

Below are the Gen 4 display screens for the blockage monitoring system on the N500C.

For complete details and information reference, the owner’s manual.

RelativeFlow Blockage configured run page

RelativeFlow Blockage configured run page

The SeedStar™ system run page displays the five major run settings. Clicking on any of the tiles will take an operator to that specific page (shown below).

Improve seed placement accuracy from the cab with TruSet™ downforce control

TruSet downforce allows operators to set downforce pressures from inside the cab. Downforce can easily be changed by the push of a button as soil conditions vary. Proper downforce is directly related to a consistent seeding depth, which leads to improved even emergence, plant density, and maturity. The range of downforce adjustability begins at 74.8 kg (165 lb) and tops out at 181.4 kg (400 lb).

TruSet screen on Gen 4 display for N500

TruSet screen on Gen 4 display for N500

TruSet screen on Gen 4 display for N500F

TruSet screen on Gen 4 display for N500F

Exclusive TruSet downforce control has taken adjustability on no-till John Deere seeding tools to a whole new level. Rather than using a valve on the tool, pressure control dials on the monitor let operators make incremental adjustments conveniently from the Gen 4 display inside the tractor cab. This also saves time and makes it easier to adapt to changing field conditions.

Seeding tool compatibility:

- N500

- N500F

NOTE: It is recommended that 15.2-m and 18.3-m (50-ft and 60-ft) machines use power beyond to run TruSet.

Display compatibility:

- Gen 4 displays

- GreenStar™ 3 2630 Display

Competitive tractors do not require add-on components for TruSet to function properly.

John Deere Seeding cover crop solutions

Why cover crops?

With proper management and the right selection of cover crops, you can slow soil erosion, improve soil health, enhance water availability, suppress weeds, control pests and diseases, increase biodiversity, and reap numerous other benefits for your farm’s health and profitability. Cover crops act as a protective shield for the soil, reducing the impact of heavy rains and wind, which in turn minimizes topsoil loss. They improve soil structure by adding organic matter and fostering beneficial soil microorganisms, which enhances nutrient cycling and retention.

Additionally, cover crops can break up compacted soil layers, improving root penetration and water infiltration. By suppressing weeds, they reduce the need for chemical herbicides, leading to more sustainable farming practices. Cover crops also provide beneficial habitat for insects and pollinators, boosting on-farm biodiversity. Furthermore, they can help in sequestering carbon, contributing to climate change mitigation. Overall, integrating cover crops into your farming system can lead to more resilient and productive agricultural landscapes, ultimately enhancing long-term profitability.

What tool works best for you?

N500C No-Till Air Drill

N500C No-Till Air Drill

The N500C model machines provide extensive crop compatibility, making them an excellent choice for customers looking to seed multiple crops and crop blends using a single tool. These machines can be customized with two unique rollers in multiple sizes to meet the specific needs of each operation. Refer to the crop compatibility link by roller below. Additionally, the N500C is capable of seeding in various soil conditions and residue types. Featuring the Pro-Series No-Till opener, it is designed to handle a wide range of conditions, from heavy residue to lightly worked soils. For more information, see the Sales Manual links below.

1590 No-Till Box Drills

1590 No-Till Box Drills

Box Drills are an excellent choice for seeding cover crops, offering simplicity and high placement accuracy. Equipped with the Pro-Series No-Till opener, the 1590 Box Drill can handle a variety of conditions, from heavy residue to lightly worked soils. The 455 and BD11 Series Box Drills, featuring a double disk opener, are ideal for tilled seed beds. They also provide wider widths and a range of spacing options. For more information, see the Sales Manual link below.

Already have an Air Seeder?

C-Series Air Cart tendering

C-Series Air Cart tendering

Any John Deere air cart compatible tools are excellent options for seeding cover crops. Air carts come with multiple tanks, enabling you to combine or blend your cover crop mixes effectively. With a wide range of meter roller options, air carts can be easily tailored to meet your specific cover crop needs and paired with the most suitable tool for the job. For more information, see the Sales Manual links below.

Key Specs

| Working widths | 10.97 m 36 ft |

|---|---|

| Spacing | 19.05, 25.4 cm 7.5, 10 in. |

| Number of ranks | two |

| Openers | Style Single disk-beveled edge Rank lock-up Yes Diameter 45.72 cm 18 in. Down pressure Hydraulic |

Sizes

| Working widths | 10.97 m 36 ft |

|---|---|

| Spacing | 19.05, 25.4 cm 7.5, 10 in. |

| Number of ranks | Two |

| Number of sections | Three |

Dimensions

| Transport height | 4.55 m 14.92 ft |

|---|---|

| Transport width | 4.37 m 14.33 ft |

| Road clearance | 21.6 cm 8.5 in. |

| Overall length | 7.5 m 24.58 ft |

| Weight before ballast | 9305, 8210 kg 20514, 18100 lb |

| Available ballast | 1179 (12+14 x 45) kg 2600 (12+14 x 100) lb |

| Frame | Cross members 10.2 x 15.2 cm 4 x 6 in. End tubes 5.1 x 15.2 cm 2 x 6 in. Hitch 7.6 x 15.2 cm 3 x 6 in. |

| Clearance from rank to rank | 133.99 cm 52.75 in. |

Tires

| Mainframe standard | (8) 11L-15, 10PR |

|---|---|

| Wings standard | (4) 11L-15, 8PR |

Openers

| Style | Single disk-beveled edge |

|---|---|

| Rank lock-up | Yes |

| Disk | Diameter 45.72 cm 18 in. Angle 7 degree (angle) |

| Down pressure | Style Active hydraulic-patented Hydraulic |

| Depth control | Description Gauge wheel beside disk Gauge wheel size 11.43 x 40.64 or 7.62 x 40.64 cm 4.5 x 16 or 3 x 16 in. Range 1.27 to 8.89 cm 0.5 to 3.5 in. Increments 0.64 cm 0.25 in. |

| In-Furrow press wheel | Material Rubber on plastic wheel Packing force 2.3 to 21 kg 5 to 45 lb Standard |

| Furrow closing | Description Trailing wheel on 20-degree vertical angle, 7-degree horizontal angle Size 2.54 x 30.48 cm 1 x 12 in. Material Cast iron Down force 12 to 20 kg 26 to 43 lb Standard |

Seed Metering

Seed Storage

Equipment compatibility (at 1.5 in. seeding depth and 8 mph)

Tractor requirements

Additional information

**Price on new John Deere Equipment only available within the LandPro Equipment selling area, pricing subject to change, see your LandPro Equipment Sales rep for details.

-

Avon, NY

(585) 226-9680 -

Batavia, NY

(585) 948-5261 -

Brockport, NY

(585) 637-3700 -

Centre Hall, PA

(814) 364-1421 -

Clarence Center, NY

(716) 741-9115 -

Clymer, NY

(716) 355-4236 -

East Palestine, OH

(330) 426-2166 -

Edinboro, PA

(814) 734-1552 -

Fairmount City, PA

(814) 764-5159 -

Falconer, NY

(716) 665-3110 -

Halifax, PA

(717) 362-3132 -

Hall, NY

(585) 526-6325 -

Macedon, NY

(585) 425-4428 -

Mifflintown, PA

(717) 436-5553 -

Savannah, NY

(315) 594-0115 -

Springville, NY

(716) 592-4058 -

Stoneboro, PA

(724) 376-3740 -

Watsontown, PA

(570) 538-3557 -

Silver Springs, NY

(585) 591-1670

**Price on new John Deere Equipment only available within the LandPro Equipment selling area, pricing subject to change, see your LandPro Equipment Sales rep for details.

New Products

Used Equipment

© LandPro Equipment 2026 | All Rights Reserved.

Site by EquipmentLocator.com