- On Sale

- Build Your Own

- Used Equipment

- New Equipment

- Trade In

- Parts

- Service

- Aged Equipment Clearance

- Buy Online

- Precision Farming

-

- The Basics Of Haymaking

- Round Baler Basics for a 460M Round Baler

- How to Load Net Wrap on a 460M Round Baler

- Top 10 Implements For Livestock Operations

- How to store large round bales

- How to set up and operate a mower conditioner

- How to use a mechanical grapple

- Pick up grass clippings using a drive-over mower deck

- Careers

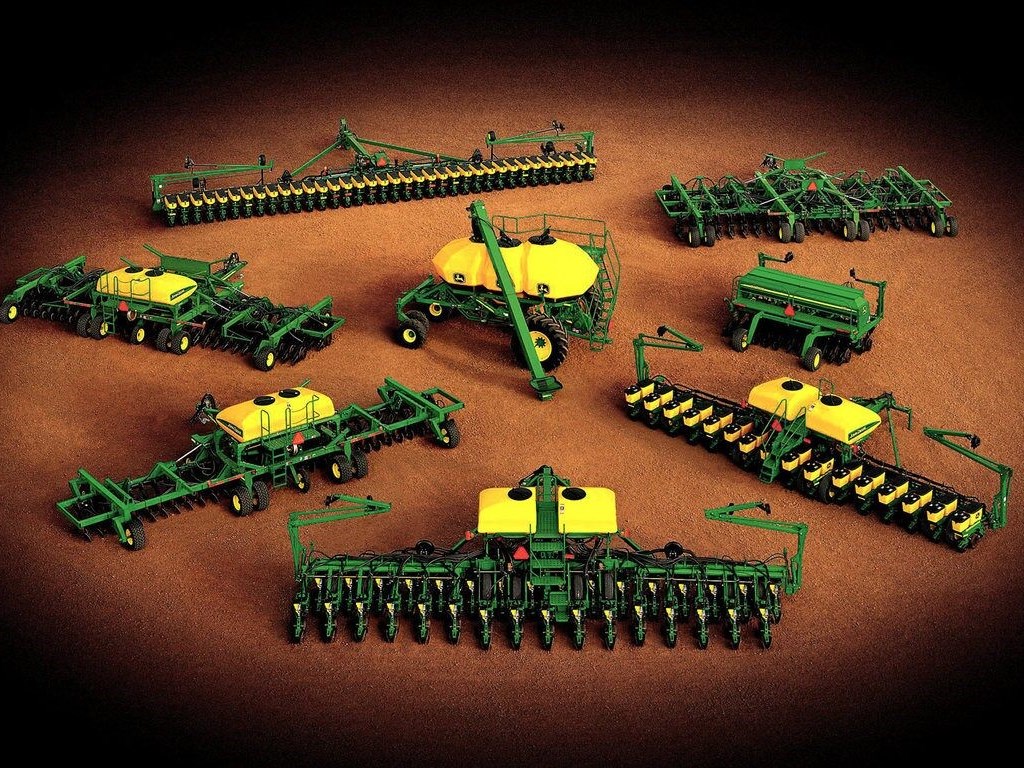

Planting Equipment

-

1705 Planter

-

1725 Integral Stack-Fold Planter

-

1725C Planter

-

1745 Compact Planter

-

1765 Flex Drawn Planter

-

1775NT 12Row30 Drawn Planter

-

1775NT 16Row30 Drawn Planter

-

1775NT 24Row30 Drawn Planter

-

1795 12Row Split 23 or 24 Planter

-

1795 16Row Split 31 or 32 Planter

-

1795 24Row20 Planter

-

DB44 24Row22 Planter

-

DB60 24Row Split 48 Planter

-

DB60 24Row30 Planter

-

DB60 24Row30/47Row15 Planter

-

DB60 36Row20 Planter

-

DB66 36Row22 Planter

-

DB80 32Row30 Planter

-

DB80 48Row20 Planter

-

DB88 48Row22 Planter

-

DB90 36Row30 Planter

-

DB90 54Row20 Planter

-

DR12 Planter

-

DR12 Twin Row Planter

-

DR16 Planter

-

DR18 Planter

-

DR24 Planter

-

MP512 Planter

-

MP516 Planter

Models

**Price on new John Deere Equipment only available within the LandPro Equipment selling area, pricing subject to change, see your LandPro Equipment Sales rep for details.

-

Avon, NY

(585) 226-9680 -

Batavia, NY

(585) 948-5261 -

Brockport, NY

(585) 637-3700 -

Centre Hall, PA

(814) 364-1421 -

Clarence Center, NY

(716) 741-9115 -

Clymer, NY

(716) 355-4236 -

East Palestine, OH

(330) 426-2166 -

Edinboro, PA

(814) 734-1552 -

Fairmount City, PA

(814) 764-5159 -

Falconer, NY

(716) 665-3110 -

Halifax, PA

(717) 362-3132 -

Hall, NY

(585) 526-6325 -

Macedon, NY

(585) 425-4428 -

Mifflintown, PA

(717) 436-5553 -

Savannah, NY

(315) 594-0115 -

Springville, NY

(716) 592-4058 -

Stoneboro, PA

(724) 376-3740 -

Watsontown, PA

(570) 538-3557 -

Silver Springs, NY

(585) 591-1670

**Price on new John Deere Equipment only available within the LandPro Equipment selling area, pricing subject to change, see your LandPro Equipment Sales rep for details.

New Products

Used Equipment

© LandPro Equipment 2026 | All Rights Reserved.

Site by EquipmentLocator.com